Fabricated Parts & Filters

Engineered for function. Trusted for a cleaner, safer world.

Discover POROSTAR®

And Get More Out Of Your Filter

Stronger. Cleaner. Smarter.

Built from multiple layers of precision woven wire mesh, POROSTAR® delivers unmatched strength, stability, and filtration performance. Its customizable laminate structure resists pressure, heat, and corrosion. This makes it the go-to solution for demanding filtration applications where consistency and durability matter most.

Explore What’s Possible

Multilayered Wire Mesh Laminates

Sintered Multilayered Wire Mesh Laminates

Sintered Multilayered Wire Mesh Laminates

W.S. Tyler’s sintered wire mesh laminates are composed of multiple layers of precision-woven wire mesh, each selected to deliver optimal filtration, flow, and structural support. These layers are permanently bonded using a proprietary diffusion bonding process that fuses the mesh at every contact point without altering the geometric integrity of each layer.

The result is a rigid, porous media that combines the benefits of surface and depth filtration with exceptional mechanical strength, thermal resistance, and corrosion protection.

Real-Word Benefits:

Maintains consistent pore size for repeatable filtration

Resists high temperatures, pressures, and corrosive environments

Offers enhanced backwashing and cleaning performance

Can be cut, formed, welded, and integrated into complex assemblies

Enables longer service life and reduced maintenance cycles

Applications:

- Gas filtration

- High-capacity liquid filtration

- Chemical processing

- Pharmaceutical production

- Automotive filtration

- Aerospace filtration

- Other separation and filtration applications

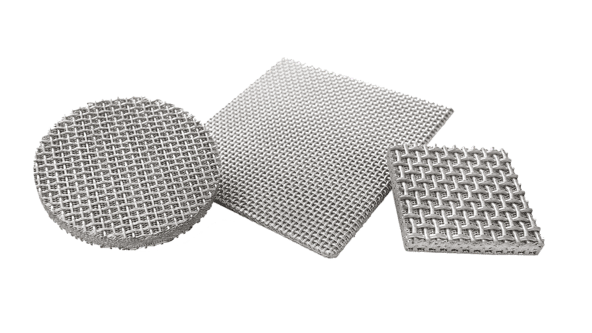

Sections and Round Parts

Sections and Round Parts

Sections and Round Parts

W.S. Tyler’s sections and round parts are single- or multi-layer components fabricated to your exact specifications. Manufactured using advanced cutting methods, including splitting, laser cutting, stamping, and rotary techniques, these parts deliver the consistency and dimensional accuracy required in today’s high-performance filtration and separation systems.

Each component can be customized by mesh type, layer count, diameter, and edge finish to meet the specific demands of your process, whether it’s filtering contaminants, controlling flow, or reinforcing structural elements.

Real-Word Benefits:

Cut with precision for tight dimensional tolerance and repeatable performance

Available in single or multiple layers for enhanced strength and filtration efficiency

Compatible with a wide range of mesh specifications, materials, and finishes

Can be edge-bound, spot-welded, or formed to fit housing requirements

Designed to reduce pressure drop, extend lifecycle, and simplify integration

Applications:

- Extruder screens

- Chromatography

- Soil-catch screens

- Automotive components

- Other screen and filtration applications

Inline Filters & Gasket Filters

Inline Filters & Gasket Filters

Inline Filters & Gasket Filters

W.S. Tyler’s inline and gasket filters are cylindrical mesh components designed to integrate seamlessly into sanitary pipe systems. Each unit features a robust wire mesh body affixed to a precision metal flange, delivering high-strength filtration performance with easy installation and replacement.

While standard configurations range from 1 to 8 inches in diameter and 1.5 to 16 inches in length, every filter can be fully customized to meet the exact flow rate, particle retention, and space constraints of your system.

Real-Word Benefits:

Designed for clean-in-place (CIP) compatibility and sanitary performance

Durable mesh construction resists high pressure, corrosion, and deformation

Tight fit and reliable sealing minimize bypass and contamination risks

Available in single or multi-layer configurations for added strength and efficiency

Quick integration into existing piping systems reduces downtime

Applications:

- Liquid and gas filtration in sanitary process lines

- Food and beverage processing

- Pharmaceutical and biotech manufacturing

- Chemical and petrochemical pipelines

- Water treatment and high-purity fluid systems

Cylindrical & Pleated Wire Mesh Filters

Cylindrical & Pleated Wire Mesh Filters

Cylindrical & Pleated Wire Mesh Filters

W.S. Tyler’s cylindrical and pleated wire mesh filters are expertly crafted to deliver high-performance filtration in compact, durable form factors. Constructed by welding precision-woven mesh at the longitudinal seam, each filter is reinforced with supportive elements to maintain structural integrity under demanding conditions.

Available in smooth or pleated configurations, these filters offer increased surface area, improved dirt-holding capacity, and efficient flow characteristics, making them ideal for systems that require consistent, long-term performance.

Real-Word Benefits:

Welded construction ensures leak-free, pressure-resistant performance

Pleated designs maximize filtration surface area in tight spaces

Customizable mesh grades for targeted particle retention

Optional end caps, cores, and reinforcements for added strength

Suitable for backflushing, cleaning, or replacement without compromising performance

Applications:

- Water purification systems

- Hydraulic and cooling fluid filtration

- Lubrication and oil filtration

- Fuel systems

- Chemical processing lines

- General-purpose industrial separation

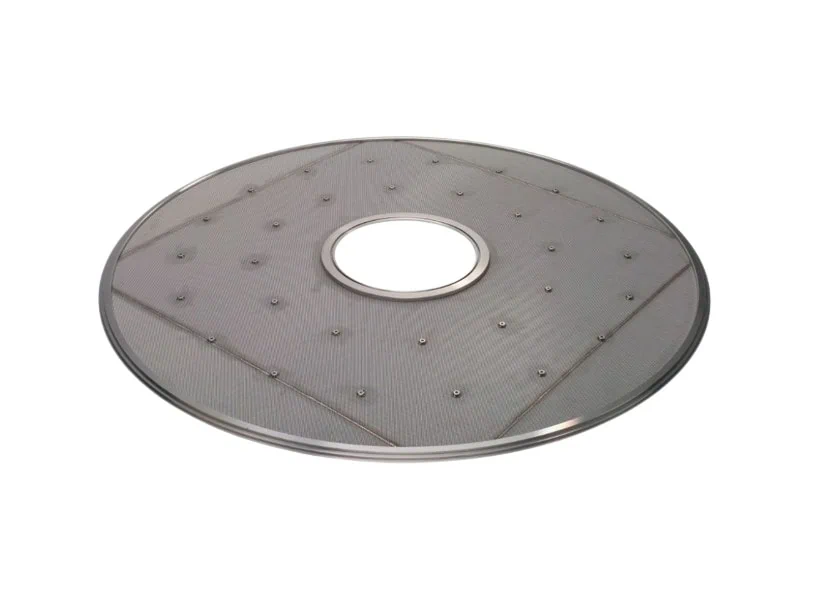

Filter Plates

Filter Plates

Filter Plates

W.S. Tyler’s filter plates are flat, precision-woven wire mesh components engineered to capture particles within a defined size range from both liquids and gases. Built for structural integrity and filtration accuracy, these plates deliver consistent performance in high-demand environments where reliability and service life are critical.

Each filter plate is available in a range of mesh specifications, materials, and dimensions, and can be integrated into filtration housings, processing equipment, or OEM assemblies.

Real-Word Benefits:

Accurate particle retention for both liquid and gas streams

Rigid flat form resists warping, pressure loss, and media failure

Designed for repeat use and easy cleaning

Wide selection of mesh types, alloys, and thicknesses available

Custom cut and framed to meet system requirements

Applications:

- Wastewater treatment

- Pharmaceutical manufacturing

- Food and beverage production

- Chemical processing

- Polymer filtration

- Other liquid-solid or gas-solid separation processes

Plastic Injection Molding

Plastic Injection Molding

Plastic Injection Molding

W.S. Tyler’s plastic injection molded wire mesh components are custom-engineered elements designed for filtration, separation, or structural reinforcement. These components combine the precision of woven wire mesh with the versatility of high-performance polymer housings.

Thanks to the customizable nature of both materials, they deliver food-safe performance, mechanical stability, and chemical compatibility across even the most demanding applications. All while remaining cost-effective, especially for high-volume batches.

We utilize advanced molding technologies to ensure the wire mesh is securely encapsulated within the plastic housing. Our meticulous injection molding process preserves the geometry of the mesh openings while enhancing the component’s overall durability.

This unique combination of materials yields a lightweight, corrosion-resistant medium that provides an ideal balance of thermal and mechanical resilience, making it suitable for a wide range of filtration applications.

Real-Word Benefits:

Stabilizes complex 3D metal mesh structures

Lightweight design reduces overall system weight efficiently

Resistant to chemicals in harsh environments

Resistant to extreme heat exposure

Cost-effective for high-volume production runs

Simplifies assembly with integrated component design

Applications:

- Police filters

- Hydrogen applications

- Household Appliances

- Heating elements

- Automotive filters

- Ventilation Grids

- Electronic cooling system

- Medical device components

- Water treatment filters

Precision-Crafted Wire Mesh That Can Overcome The Toughest Filtration Roadblocks

Filters that allow particle bypass or degrade over time

Woven wire mesh provides precise and repeatable pore sizes, ensuring consistent filtration performance throughout the component’s lifecycle.

Filters corrode or deform in harsh, demanding conditions

Woven wire mesh can be manufactured from stainless steel, Inconel, Hastelloy, and other alloys to withstand extreme process conditions.

Restricted flow and reduced system efficiency

Wire mesh allows for high permeability while still capturing targeted particle sizes, supporting higher flow rates with minimal pressure loss.

Frequent replacements and system interruptions

Fabricated wire mesh parts are engineered for strength and durability, reducing maintenance intervals and minimizing unplanned downtime.

Standard filters don’t fit specific system configurations

Fabricated mesh components can be custom-cut, pleated, welded, and formed to fit even the most complex geometries and flow requirements.

Excess waste not meeting regulatory demands

Woven wire filters are reusable, easy to clean, and can be fabricated for sanitary and FDA-compliant applications, supporting cleaner, safer operations.

Your Mesh, Your Way

From shape and size to structure and surface treatment, every wire mesh component we fabricate is tailored to your exact specifications. Whether you need a single prototype or high-volume production, we work with you to deliver mesh solutions that fit your process, not the other way around.

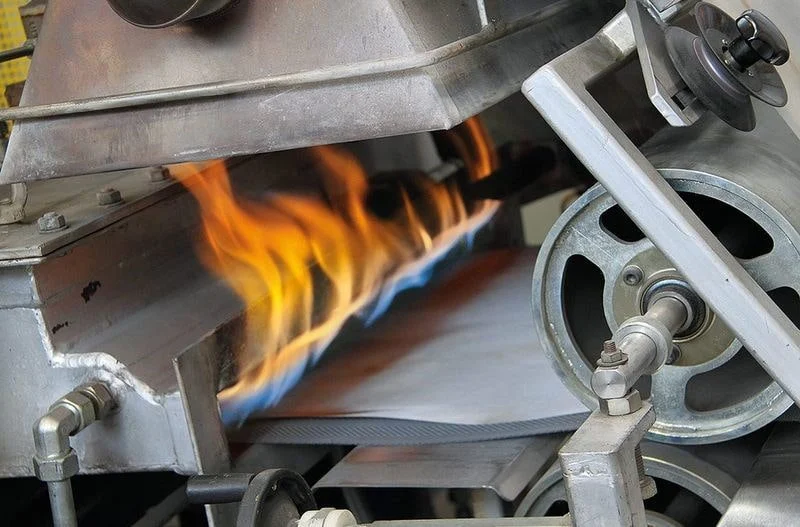

Annealing/Sintering

Annealing/Sintering

Annealing/Sintering

Our heat treatment processes, including annealing and sintering, are carefully controlled to enhance the durability, formability, and functional performance of your wire mesh components. By relieving internal stress, improving structural integrity, and ensuring consistent pore stability, heat treatment plays a critical role in extending product life and optimizing how your mesh performs in demanding applications.

The result is a stronger, more reliable mesh that is easier to work with, lasts longer in service, and performs exactly as your process demands.

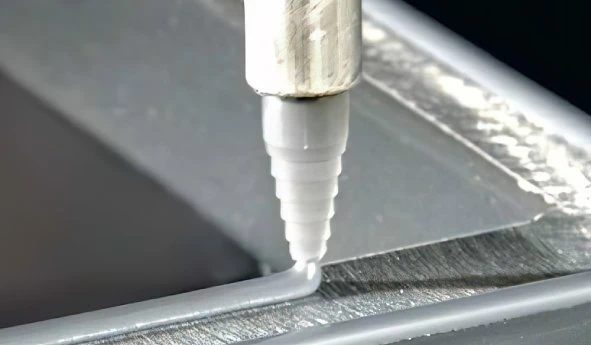

Adhesion

Adhesion

Adhesion

Adhesives are used to seal and protect welded joints, borders, and seams in your wire mesh components, delivering a clean, reliable bond that stands up to real-world demands. Whether your application requires high-temperature resistance, food-grade compliance, or chemical compatibility, our adhesive techniques ensure consistency, durability, and performance across every part.

This ensures your mesh components stay sealed, secure, and ready to perform in even the most critical environments.

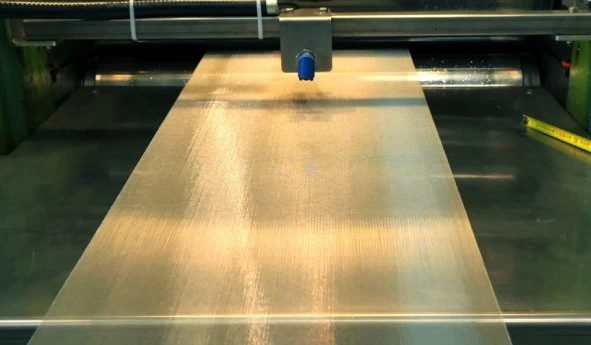

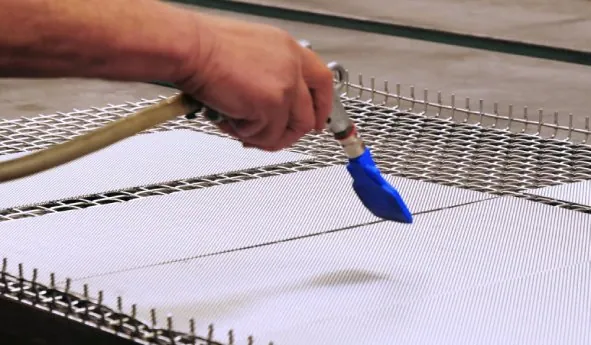

Calendering

Calendering

Calendering

Calendering enhances the versatility, rigidity, and overall performance of your wire mesh by compressing it to a precise thickness and smoothness. This highly controlled process ensures uniform mesh structure, improved handling, and better bonding or layering in downstream applications.

The result is a wire mesh that is easier to fabricate, more consistent in performance, and tailored to meet the exact demands of your process.

Cleaning

Cleaning

Cleaning

Our cleaning processes combine degreasing, aqueous cleaning, and state-of-the-art ultrasonic technology to remove contaminants from rolled, coiled, or single wire mesh components. This ensures every part arrives clean and process-ready, supporting optimal performance, product integrity, and extended service life.

Clean mesh leads to cleaner results, minimizing risk, maximizing efficiency, and protecting your process from the start.

Cutting Processes

Cutting Processes

Cutting Processes

From standard shapes to complex custom geometries, our advanced cutting methods(rotary and stationary blades, splitting systems, water jet, plasma, and laser cutting) ensure your wire mesh components are produced with exceptional accuracy. Whether you’re working with single-piece parts or high-volume multi-part runs, each cut is made to meet your exact specifications.

Consistent, clean cuts reduce integration time, improve part performance, and keep your production moving with confidence.

Pressing / Deep Drawing

Pressing / Deep Drawing

Pressing / Deep Drawing

Our fully automated pressing and deep drawing capabilities allow for the creation of precise, integrated wire mesh profiles that support even the most demanding filtration and screening applications. These techniques push the limits of formability, enabling the production of embossed, perforated, or formed components with accuracy and repeatability.

Whether you need large-scale production or one-off prototypes, each part is built to perform with consistent quality and dimensional integrity.

Welding

Welding

Welding

Multiple layers of wire mesh or fully formed components can be permanently joined using advanced welding techniques that ensure structural integrity and performance under pressure. Available welding methods include plasma, TIG, MIG, MAG, and resistance welding, with both seam and spot welding performed to the highest precision.

Each weld is executed to meet your application’s strength, cleanliness, and dimensional requirements.

Straighten and Stretching

Straighten and Stretching

Straighten and Stretching

Our straightening and stretching processes apply controlled tension and alignment to eliminate bends, waves, and other distortions that compromise mesh flatness. The result is a uniform, stable surface that improves the fit, function, and appearance of your final component.

Perfectly flat mesh ensures easier fabrication, better sealing, and more reliable performance in your application.

Plastic Injection Molding

Plastic Injection Molding

Plastic Injection Molding

Plastic injection molding allows you to combine the precision of woven wire mesh with the strength and versatility of molded plastic. This process enables the creation of highly functional, one-of-a-kind components that are lightweight, durable, and easy to install.

Ideal for applications that demand seamless integration, repeatable quality, and enhanced part performance.

Stamping and Punching

Stamping and Punching

Stamping and Punching

Our stamping and punching processes are designed to produce wire mesh components with exact shapes and detailed designs at scale. Using advanced equipment and expert craftsmanship, we achieve tight tolerances and repeatable quality across high production volumes, reducing manufacturing costs without compromising performance.

Efficient, accurate, and scalable; ideal for turning complex mesh designs into production-ready parts.

Industries We Serve

Discover how woven wire rolls and cut-to-size pieces enable you to craft best-in-class solutions in-house while maintaining a reliable wire mesh inventory.

Aerospace Automotive Chromotography Pulp and Fiber Water Filtration Plastics and Extrusion Oil and Gas Carbon capture

More Than a Wire Mesh Supplier.

An Extension of Your Strategic Team.

With over 150 years of wire weaving expertise and the global support of Haver & Boecker, W.S. Tyler is built on precision, reliability, and partnership.

Your Questions Answered:

Capabilities, Services, and More

Woven wire mesh can be custom fabricated into a wide range of filtration components, including filter discs, cylindrical filter elements, multi-layer wire mesh laminates, strainers, baskets, and die-cut mesh gaskets. These parts are commonly used in industries like chemical processing, oil and gas, food and beverage, and water treatment.

Fabrication techniques such as welding, laser cutting, press punching, and plastic overmolding allow you to achieve highly precise dimensions and performance characteristics. Whether you need a high-flow support layer or a fine micron retention filter, custom wire mesh fabrication ensures a tight fit and dependable performance within your existing system architecture.

Selecting the correct wire mesh specification is critical for ensuring reliable performance in industrial filtration. This includes determining the appropriate mesh count, wire diameter, weave pattern, open area, and metal alloy. These factors directly affect filtration efficiency, flow rate, differential pressure, and resistance to corrosion or heat.

To make an informed selection, define:

- Target micron rating or particle retention level

- Process media (liquid, gas, slurry, etc.)

- Operating temperature and pressure

- Required chemical compatibility

Working with a mesh manufacturer ensures you get a solution that matches your process goals while avoiding costly downtime and frequent replacements.

Custom woven wire mesh filters are designed specifically for your process parameters, offering far more value than generic or off-the-shelf components. When you invest in a tailored mesh solution, you benefit from:

- Improved filtration precision through mesh layering and exact micron control

- Optimized flow dynamics, reducing clogging and pressure drop

- Longer service life, thanks to high-quality materials and expert fabrication

- Ease of integration into complex or space-limited equipment

This level of optimization is essential for sectors such as aerospace, pharmaceutical manufacturing, and food processing, where performance, compliance, and reliability are non-negotiable.

Compared to disposable media like paper or polymer filters, woven wire mesh offers superior durability, heat resistance, and reusability. Unlike sintered metal filters, woven mesh provides more customizable pore structures, shorter lead times, and easier integration into unique component shapes.

Key advantages of wire mesh filters include:

- Reusable and cleanable construction (ideal for high-throughput or CIP systems)

- Stable pore sizes for predictable, repeatable filtration

- Broad alloy selection including 316, 430, and 904L stainless steel

- Scalable fabrication for high-volume production or one-off prototypes

For applications demanding long-term filtration efficiency, high mechanical strength, and chemical resistance, woven wire mesh remains a top-performing, cost-effective option.

To receive an accurate quote and accelerate the design of your custom wire mesh filter, be prepared to provide key details such as:

- Filtration application (e.g., hydraulic oil filtration, water purification, polymer extrusion)

- Desired micron rating or mesh count

- Part dimensions and shape requirements

- System specifications (operating temperature, pressure, and flow rate)

- Preferred metal alloy or coating for corrosion or heat resistance

- Any applicable regulatory or industry standards (FDA, NSF, ISO, etc.)

This information allows the manufacturer to recommend the ideal weave type, layering structure, and fabrication process, ensuring the final product delivers maximum performance and compliance.

Discover The Potential Of Woven Wire Fabricated Parts and Filters

How Much Do Extruder Screens Cost? (Factors and Cost Savings + Video)

The proper filtration of recycled material is essential to manufacturing products that function as intended. Extruder screens, also referred to as screen packs, have been…How Woven Wire Mesh Funnel Screens Affect Low-Pressure Die Casting

From automobile parts to furniture, the impact of low-pressure casting is all around. To ensure efficient operation and high-quality products, engineers must use adequate funnel…Comparing Filter Media: Woven Wire VS Wedge Wire

When it comes to the filtration world there are endless types of material you can use: metal, paper, fiber, polymer, ceramic, etc. All of these…8 of the Best Stainless Steel Filter Manufacturers

All filtration operations rely on filter media that delivers accurate filtration, adequate throughput, and maximum durability. This is why woven wire filter cloth is such…Wire Mesh Filters: What You Need To Know Before You Buy

Woven wire mesh is arguably one the most versatile materials in the world, as it can be formed to accommodate almost any filtration or design…